Case Study

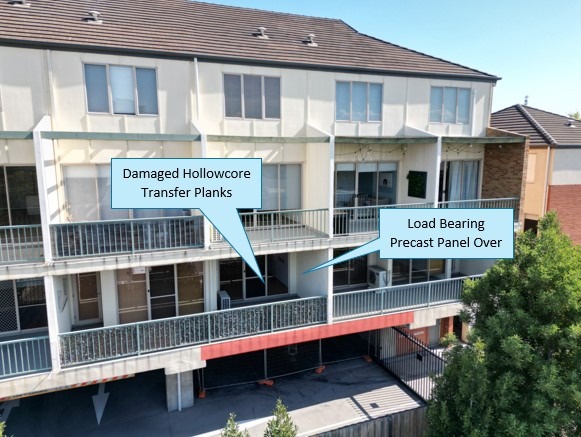

A car fire in the ground floor carpark of a four-story apartment building structurally compromised several first-floor hollowcore concrete floor planks beyond repair.

Challenge

Imparta Engineers discovered several of the hollowcare planks were critical structural elements which supported levels directly above. They were unable to be replaced like-for-like due to constructability issues.

Specifically, the crane would not be able to install new precast hollowcore planks from above without demolishing the upper levels of the building first.

Engagement

Imparta Engineers were engaged to provide an alternative solution which would allow for the repairs to be undertaken within the access constraints which exist at the site.

Imparta Engineers initially attended the site to undertake concrete testing using a Schmidt Hammer to determine the severity of the damage. Imparta Engineers also met with the Loss Adjuster and Unit Owners to discuss the proposed repair options, and associated complexities and risks which each proposed solution.

Solution / Methodology

The detailed solution provided by Imparta Engineers was agreed upon by the Loss Adjuster and Unit Owners, and involved the following steps:

- Undertaking a full dilapidation survey of the building.

- Relocating all occupants of the building for the duration of the construction works to ensure safety of the occupants.

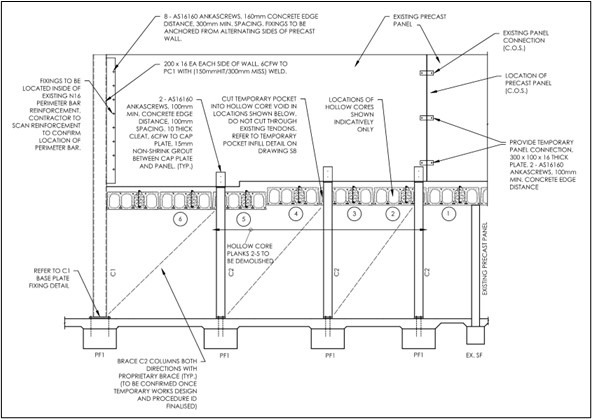

- Scanning the existing concrete to determine the size and location of existing reinforcement.

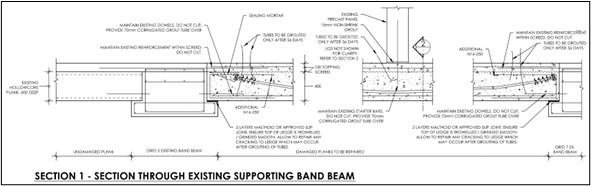

- Providing new footings for the extensive propping which would temporarily support the building.

- Propping the backspan of the existing floor slab.

- Carefully punching through the existing damaged Hollowcore planks to prop and brace the load-bearing precast panel above, while avoiding damaging the existing prestressing strands.

- Providing a temporary catch deck to safely demolish and remove the existing floor.

- Carefully demolishing the damaged floor planks while retaining the existing starter bars.

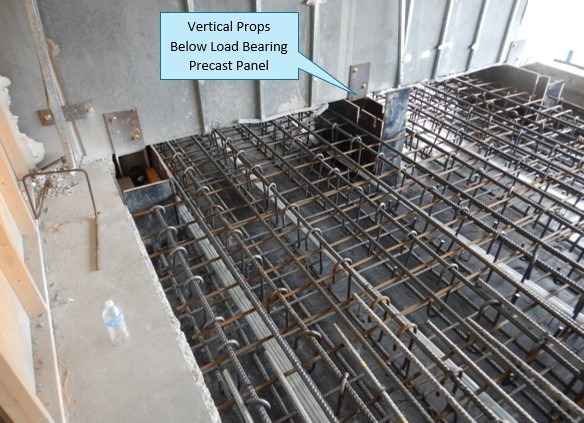

- Pouring a new in-situ new post-tensioned floor slab, leaving pockets in the slab for the vertical propping supporting the precast panel.

- Pouring a new screed layer to tie the new slab into the existing starter bars once stressing of the new floor slab had been completed.

- Removing the propping and infilling the pockets which remained in the slab.

Quality Control & Customer Satisfaction

Imparta Engineers undertook inspections at all critical stages, including inspection of the temporary propping, footing reinforcement, and slab reinforcement, to ensure that the construction was in accordance with the design documentation.

The ongoing communication between Imparta Engineers and the Unit Owners ensured that all stakeholders had a full understanding of the complexity, nature and time frames involved with the repair works.

Results

The solution provided by Imparta Engineers allowed the repairs to be undertaken without demolition of the upper levels of the building, significantly reducing the cost to the Insurer.

Additionally, the time frame of the project was reduced, therefore minimising the cost of relocating the occupants of the building during the construction works.